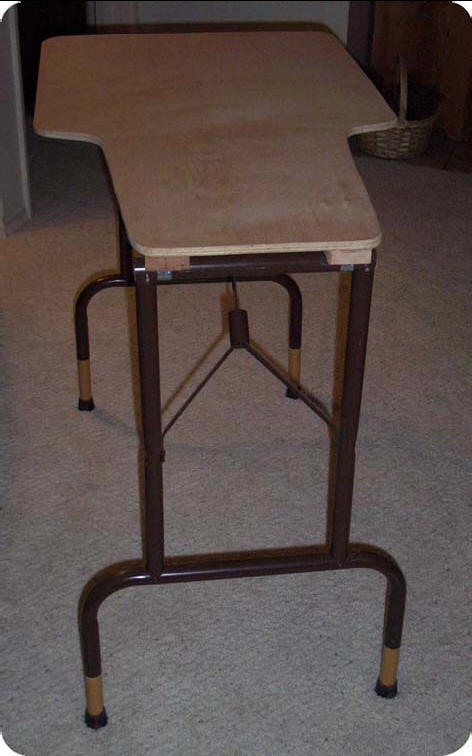

This portable shooters bench design is not completely

original, but I have not seen another like it. It is very stable in field

conditions, compact, simple to set up and not outrageously heavy, usually

17-20lb. No special tools are necessary to assemble it and you can size it to

suit your needs, within certain limitations.

This idea developed when a friend showed up for a desert

shoot with an 8-foot long banquet table. He was using it as a shooting bench. It

was too low, too long and too heavy to suit me. But it lit a fire in me to

improve on what he had. I scrounged up a set of legs from a broken banquet table

and created something taller, lighter and sized to fit my shooting needs. The

result is similar to (but not exactly like) what you see here.

Please note that there are different styles of table legs

available and each may require some variation in mounting design. I have come

across three different styles that work well. I prefer the size found on the

smaller 24"x48" tables *. Only because they are narrower in the leg spread (side

to side).

* These smaller tables I find I can buy NEW (the whole table)

when on sale at Office Depot, Office Max and a few other discount office supply

stores for about $20. That is now my source for table legs. However, I now have

a few tabletops in the garage that I have little or no use for. (cut in half

lengthwise they make good shelves for the garage).

Current table materials:

Table (legs or table)

Top (24" X 48" sheet of 5/8" CDX plywood) (or you can use

the original table top and save money, but they are pressed board and heavy)

Clamps (to attach the legs to the table, this type of clamp

is designed to attach pipes to the studs in a house frame etc.)

Molding (a trim rail around the front area of the table to

keep thing from rolling off) (an OPTION)

Wood glue

Wood screws 1¼" long and ½" long

Additional wood for leg mounting

Leg tips (heavy duty table leg caps or crutch tips)

Dowel to extend the legs (broom handle – Home Depot).

Stain and finish. (Model table not finished yet)

** I prefer the legs shown in the photos are over the box frame

leg sets, but either is equally good for this purpose.

Assembly:

Determine the size you want/need. By trial and error I

discovered that 40" in length was about the right size for my needs. I initially

made mine to fit in the back of my SUV. Forty inches is also long enough to

place the front sandbags or rest anywhere under the stock and not have it

falling off the table. I assembled one 35" long to fit in the trunk of a

friend's small car.

To keep the weight as low as possible I started with a full

24" width and found it to be more than I needed. I trimmed it down (mainly to

reduce weight) and settled on a final width of 22". However, the legs were 24"

wide. NOTE: The smaller table leg sets (available only on the 24x48" tables) are

only about 20" wide (refer back to first paragraph).

I used a saber saw to cut two recesses at the rear of the

table top to allow shooting from either side. I did this because I often shoot

left-handed. If you never shoot left (or right) handed, you may decide to make

only one cutout. If you do this however,

remember to mark the top so the leg can be mounted in the

center. The width at the rear is about 13". This is wide enough to mount the

rear legs with a little left over on each side. This width is also adequate to

settle your elbow comfortably.

After you have your top the size and shape you want, radius

the edges with a file or router then sandpaper. Next I applied glue to the

entire edge to seal it and prevent splintering of the plywood. I then put on one

coat of clear finish. I didn’t go to any extremes to make this a beautiful

table, only functional. You can apply paint if you wish, but I suggest lighter

colors, as the darker ones will get real hot in the sun.

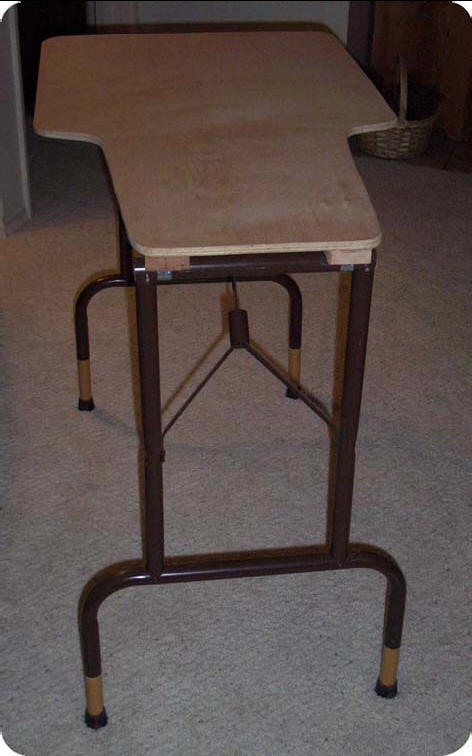

Layout the leg locations. Because of the short length of the

top, the legs will overlap one another when folded. If both legs are mounted

directly to the bottom side of the table, one set will lay flat and the other

will point skyward at a 5-10 degree angle. This is not convenient to pack in

your vehicle or to store in the garage. If that is not a problem, skip the next

section about adding blocks.

I added blocks to the bottom of the tabletop that allows the

legs to lay parallel when the table is folded. You can use one large block,

however, individual blocks (per photo) are lighter. Raising one set of legs

allows both leg sets to lay flat and parallel. On this model I used standard 1"

thick pine and it in not really 1" thick so the legs do not lay quite parallel

but close enough for me. If you want them parallel you need to make your blocks

exactly the thickness of the tubing.

Attach the block(s) of wood to the bottom side of the

tabletop with glue and the 1¼" screws. Attach the legs to the block with screws.

NOTE: install the two blocks at the end of the table first. Then install the

legs to those blocks. Make sure they are straight. With the legs folded parallel

to the surface of the top, mark the position of the support block for the

support strut. Attach the block at that location with glue and screws. Again lay

the legs parallel to the top and attach the support to the block.

Now for the fun part! The legs as they are made were too

short to suit me and I am only 5'7". I don't like sitting at the shooting bench

all hunched over feeling like some kind of contortionist. This posture is not

conducive to relaxed shooting. After a day shooting squirrels or prairie dogs

the back suffers. To make the table height comfortable I had to raise it four to

five inches.

Additionally, I like a stool that is high enough to allow my

feet to be flat on the ground with my thighs parallel to the ground. That is

about a 16" to 18" tall stool. I use a folding campstool with cloth seat. The

model I like is camo patterned and has a storage pouch below the seat.

To raise the table I added some length to each of the four

legs. The leg set mounted on the block is about one inch longer than the other

set. The idea is to extend one set of legs about 4" and the other legs about 5".

Depending on the diameter of the leg tubing you may need to

consider different leg extensions. In this case I was able to use broom handle

stock. The tubing on the set in the photos is about 1.15" outside diameter. If

the dowel is too large a diameter you can split them lengthwise with a hacksaw

for a couple inches and force them in, or you can shave them down with a block

plane, spoke shave, or even a pocketknife. If your dowel stock is too small in

diameter you may be able to wrap tape around it as a shim. I haven’t tried that,

I prefer splitting or trimming to get a good fit. Once the dowels are in place,

lock them with a screw. Drill a hole in the side of the leg and into the wood.

Insert a screw to hold the legs tight. This is just an insurance policy so you

don’t loose a leg somewhere when you aren’t looking. A three-legged table is

quite wobbly.

On a couple of tables I was able to use electrical conduit.

The next several paragraphs deal with installing conduit type leg extensions. If

you used dowel you may find some tips in this material also.

Many of the leg sets I have encountered are about one inch

outside diameter with something less than

"

inside diameter. These instructions apply to that particular size of leg tubing

(not the model here). The conduit is about 7/8" outside diameter. In this case,

the dimensional difference makes for a very tight fit. The objective is to force

the conduit into the bottom of the leg. So, two options are available, cut the

table leg vertically to allow it to expand, thus the conduit will slip inside.

Or, cut the end of the conduit vertically and compress it to fit into the leg.

DO NOT cut the table legs; DO cut the conduit (I know, I made that error once).

Cut four lengths of the electrical conduit, two 6½" long and

the other two 7½" long. Measure 1½" from one end of each section and put a piece

of masking tape around the conduit there. From that same end, cut across the

middle down to the tape. Make a second cut 90 degrees to the first. After doing

this you now have four tabs 1½" long. If you have the same trouble I have with a

hacksaw, your cuts are not straight, but that is not a critical issue here.

Next, "bell" the end of each table leg to help get the

conduit started into the leg. The metal of the legs is relatively easy to shape

with a steel bar or long screwdriver. Put the end of the bar, screwdriver of

whatever you are using, inside the leg about 2" and rotate while applying

pressure outward at the opening. The leg is now "Belled".

Now you are ready to install the leg extensions to the leg

sets. Remove the tape from the conduit. Put Press the four tabs at the end of

the conduit as tightly as possible and push the conduit into a leg. Use a hammer

and drive the conduit in until it is very tight.

Repeat the step with the other three legs. Make sure the two

shorter conduit extensions are on the leg set that is raised on the block. If

not, you will never get the table to level. Once these conduits are in place

they may be very difficult to remove, next to impossible in fact.

Measure the conduit in each leg set and make sure they extend

the same distance from the end of the original leg. The table should stand level

on a level surface. If not, adjust the leg extensions with a

tap of a hammer or trim the offending leg shorter with a

file. Done?

Now add the crutch tip. I use crutch tips here because they

are heavier duty than the average rubber or plastic table leg caps.

There are a few side effects of making this shooting bench. I

must warn you that your shooting partners may want to use yours, not theirs,

because yours is, stable and lighter than theirs. Also, you may find it quite

useful in the garage as a small convenient worktable or reloading bench. I set

mine up and clamp the rifle vice to it for cleaning or other gun work.

If you have any questions about the instructions or have

suggestions to improve this portable-shooting bench please contact me at

[email protected]

or

call me (909) 785-4986.

If you do not have the means to make one of these benches I

can be talked into doing it. To break even on this it will cost the buyer parts

and shipping + $30 labor. The current material cost (2001 prices) runs about

$55-$65. The Labor included my expense or running around town picking up the

materials, thus I usually come out only a few bucks above even.

Your comments and suggestions may make this more useful to

hundreds of others that are looking for an inexpensive, simple, light,

convenient, and portable shooting bench. And feel free to pass the instructions

along to your friend. I hold no patents or rights here.

I have received suggestions like adding a piece of half-round

molding around the top to make a small fence so things will not roll off the

top. One suggestion was to cut a hole large enough to hold a drink cup.

Since I first wrote and published this article in the

California Varmint Callers website table legs have become almost impossible to

find in my area. I used to get them through Harbor Freight, but they no longer

carry them and I have not yet found another reliable commercial source. I have

scrounged a few sets by asking at churches and schools if they had any tables

with damaged tops. However, as I state in the beginning I now just wait for the

sales and buy new tables, remove the legs and start from there.

Have a Safe Shooting Day.

For assistance, more information or if you have additional

ideas that can improve this bench, please send me a note at

[email protected]

Have a Safe Shooting Day.